More and more companies are departing China

More and more companies are departing China

How attractive is the factory of the world still?

For a long time, China was the ideal location for European companies to offshore all or part of their production. But the “factory of the world” has lost much of its popularity in recent years. More and more European companies are saying they are considering reshoring and nearshoring production lines. This development has been accelerated by the covid pandemic and the way China handled it. How attractive is the factory of the world really?

The main consideration for offshoring in China has always been that production is much cheaper there. Whether it is still much cheaper is now highly questionable. China was a low-wage country twenty years ago, but it hasn’t been that way for quite some time now. The advantage of cheaper raw materials has also reduced dramatically. Add to this the sharply increased transport costs, and it is clear that the calculation no longer leads to the desired outcome.

Deteriorating political climate

Financial considerations carry the heaviest weight in offshoring, but other considerations also play a role. Many entrepreneurs and expats say the political climate in China has deteriorated sharply over the years. Since Xi Jinping became president in 2013, the Communist Party of China has tightened its grip on society. And this has come with tangible consequences: more control, more oppression, increasing nationalism and an increasingly unfriendly attitude towards foreigners. A completely different factor that contributes to the quality of life is the poor air quality in Chinese industrial cities. Smog is still a familiar and annoying phenomenon.

Gamechanger: the covid pandemic

It has already been said: the discussion about offshoring and reshoring has become more urgent following the consequences of the covid pandemic. The zero-covid policy used by the Chinese government to tackle the pandemic had a profound impact on people’s lives. Entire neighbourhoods were closed off, mass testing took place, and people had to stay indoors. For example, it was impossible to buy food or water in Shanghai for the first weeks of the lockdown because the shops were closed. The pandemic also had major consequences for (production) companies. Many factories were closed during the lockdown. Other factories were running at half capacity. Travel restrictions delayed deliveries and transportation. The government’s handling of the lockdown in Shanghai seriously damaged confidence among foreign entrepreneurs.

How will China proceed after their zero-covid policy?

The Chinese government has now said goodbye to the zero-covid policy. It has done so under pressure from increasing domestic protests and declining growth in the Chinese economy. However, the concerns of foreign companies have not disappeared. For example, not all the restrictive measures have been lifted. A PCR test is still required to access schools and hospitals. Under the new guidelines, lockdowns may still be applied in regions designated as “high-risk areas”. In principle however, those lockdowns will be less drastic and not last as long. In the meantime however, the outside world has no insight into the size of the current wave of the infection. What if it turns out to be much bigger than the Chinese government expected?

Reducing risk: reshoring and nearshoring

In this situation, it is no wonder European companies with production sites in China are reconsidering their position. China was a country that offered security for a long time: the situation was stable and government policy was predictable. But that has now changed. Do you want to consider going through another strict lockdown? That’s a spectre companies do not want to even think about. So should we be completely dependent on China for production? Well, that’s a no-go as well. In Europe, we learned our lesson thanks to our dependence on Russian gas. Some companies have decided to bring all their production back to home base. Other companies want to spread their risks more evenly. They are setting up a parallel production chain in addition to a Chinese production chain. Nearshoring – production activities taking place in the vicinity of the parent company and within Europe – can be an interesting option in this case. The EU pays more attention to the economic interests of European companies and is transparent to citizens and companies in the way it votes about, for example, covid policy. In addition, economic benefits can also be achieved close to home: lower transport costs plus higher performance from excellently trained and highly motivated employees.

Reshoring, offshoring and nearshoring: what do you think?

Finding a suitable production location is not easy these days. There are numerous factors to consider. To name a few: armed conflicts, different political systems and cultures, specific national laws and regulations, the cost of labour and transport and policies regarding pandemics and other health risks. We are very curious to know which region is most attractive to you and your company right now. Therefore, we have put together a poll. Would you please express your opinion via this link. Your cooperation is greatly appreciated! No doubt you would like to know what fellow entrepreneurs think. We will return to the results of the poll in our next newsletter.

Customer instructions for packaging and transportation

Customer instructions for packaging and transportation Sustainability

Sustainability

Sheet metal cutting is all about quality and cost efficiency. Therefore, the ERP system and the laser cutting machine must communicate well with each other in all phases of production control. “The biggest challenge is to always ensure the correct data gets from the ERP system to the laser cutting machine so the machine can provide feedback. Working with SixPointTwo, it was decided to first define the optimal process of production and control”, says KleinJan. He knows the ERP system through and through. “At the time, I was also involved in its implementation.”

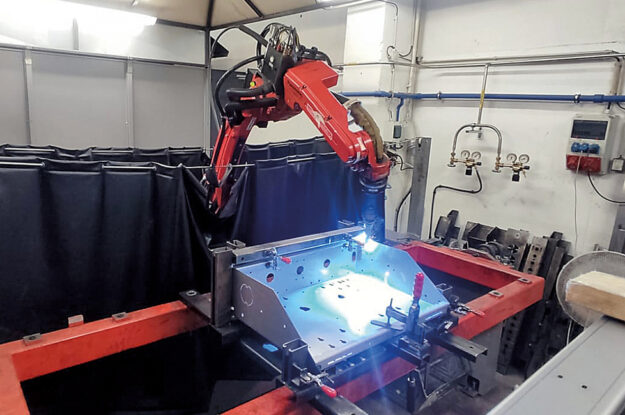

Sheet metal cutting is all about quality and cost efficiency. Therefore, the ERP system and the laser cutting machine must communicate well with each other in all phases of production control. “The biggest challenge is to always ensure the correct data gets from the ERP system to the laser cutting machine so the machine can provide feedback. Working with SixPointTwo, it was decided to first define the optimal process of production and control”, says KleinJan. He knows the ERP system through and through. “At the time, I was also involved in its implementation.” SixPointTwo first approached Valk Welding in 2016. The expansion of our production capacity necessitated additional welding capacity. “Especially the welding for serial production runs”, says van Boxel. A further increase in production led to the purchase of a second welding robot in 2021. “Like the first, this is also a complete welding robot system in which the welding robot is mounted on a stable H-frame. We also supplied DTPS: the software package for offline programming.”

SixPointTwo first approached Valk Welding in 2016. The expansion of our production capacity necessitated additional welding capacity. “Especially the welding for serial production runs”, says van Boxel. A further increase in production led to the purchase of a second welding robot in 2021. “Like the first, this is also a complete welding robot system in which the welding robot is mounted on a stable H-frame. We also supplied DTPS: the software package for offline programming.”