The devil is in the details…

The devil is in the details…

Steel constructions fully protected

Every detail matters. How often do you hear successful artists, athletes and entrepreneurs say that? It’s also the motto at the company responsible for a total of 3,000 tonnes of steel structures for a new construction project in Veldhoven. Of course, the client for this project is also very interested in details. In fact, this client is a global market leader that excels in precision technology right down to the square nanometre.

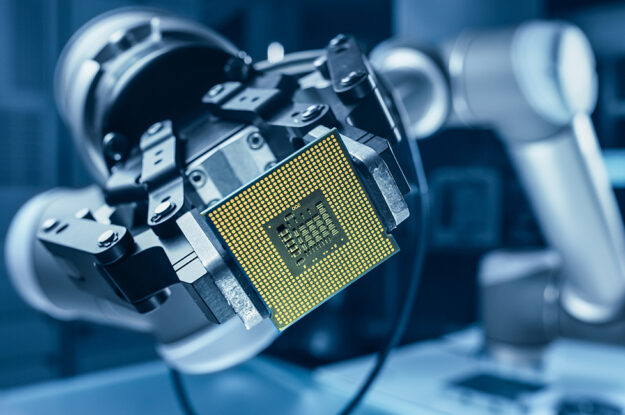

At De Run 6000 in Veldhoven, the steel structures for the exterior of the new commercial buildings are already in place. The steel structures for the interior will be completed in the first quarter of 2024. Then it will be time to install the clean rooms, which will soon house research for the development of new machines for microchip production (IC’s).

GS Steel Group: preferred supplier

The client in Veldhoven is ASML, of course. The steel structures are the work of the GS Staalwerken Groep, where Henk Verhagen is responsible for procurement. “GS Staalwerken Groep has been working for ASML for many years; we are a preferred supplier. Across our branch locations, I am responsible for sourcing the steel needed for our projects. This amounts to about 15,000 to 20,000 tonnes of steel per year.”

Project-based procurement

In procurement, every detail counts. “I source our steel on a specific project basis. Once the design for a project is ready, we must install it within six to eight weeks. That means we are always working under considerable time pressure. The structure should be completed as soon as possible, because only then can the contractor start their work.” Waiting until the design is final is not an option. “That would simply be too late. So, I make sure we know in advance what type of steel profile we need. This allows me to purchase 80-90% of the required material at raw length, directly from the factory.” The specific details can wait until the design is finalised. “At that point, we know at which exact lengths the steel beams need to be cut and where, for example, the tabs and holes will be.”

Multidisciplinary team

Every project is discussed within a multidisciplinary team, which, in addition to Henk, includes the Project Leader and colleagues from Planning, the Drawing Office, and Work Preparation. “We decide how to approach our work on a project-by-project basis. Our goal is to have the steel profiles reach the construction site in the most economical way possible. Therefore, during the procurement process, I also take into account where the profiles are made, where they will be used, and the time it takes to install them. I also keep an eye on the planning.” The ASML project was a challenging puzzle. “The profiles used are not standard profiles you can buy from just any steel company. We were looking for a company that could manufacture them in the desired quantities as well as deliver them just-in-time. And we found them.”

Special detail

Essentially, standard details are purchased from suppliers who have them in stock. “However, for ASML, we also needed a detail that could be custom-made and be ready within six to eight weeks. It involved 25 tonnes of stainless steel sheet metal used to protect the steel columns of our structures while the concrete for the floors is being poured. What’s more, this stainless steel sheet metal also protects the storeys below if the sprinkler system is activated. This is important, because everything must be in perfect condition and remain that way for the clean rooms that will soon be installed within these steel structures.”

Choosing SixPointTwo

There were two candidates in the selection process: a Dutch company and SixPointTwo. In his previous job as a buyer, Henk had already worked regularly with SixPointTwo. “In my opinion, SixPointTwo would be an extremely suitable partner for this job. I knew that SixPointTwo had the capacity to deliver within five to six weeks and that Willian van Eerd never shies away from a challenge and always takes his responsibilities seriously.” Based on his experiences, Henk decided to suggest to the management that they should go with an Eastern European company this time around. “And also because of the purchasing advantages we were able to negotiate, SixPointTwo was chosen.” That choice turned out to be the right one. “It has been a positive collaboration. We did encounter some challenges with the drawings and the files we provided. SixPointTwo did a fantastic job converting and processing them – everything they supplied was 100% correct.”

Focus on speed and flexibility

The ASML project will be completed in 2024. “By then, we will have been at work for one year.” A new project is the car park of the University Hospital in Ghent, Belgium. “With 3,000 tonnes of steel structures, this truly is an XXL project: It includes materials weighing 500 kg per metre. That is heavy and specialised work.” The GS Staalwerken Groep has the professionals in-house to handle it. What’s more, the organisation is focussed on speed and flexibility. “In addition to our 500 permanent employees, we have a flexible shell that allows us to scale up and down easily. And, we have machines that can basically run 24 hours a day.”

Reputation

The GS Staalwerken Groep has five locations, each with its own specialism. The headquarters is in Helmond, with branch locations in Bladel, Nuenen, Bergeijk and Oude-Tonge. The website features various examples of special projects, such as the EYE Film Museum in Amsterdam. “As we always say: If our competitors can’t do, then we can. Our flexibility is a real asset in this respect. We can switch gears quickly, and we are not afraid to give our customers short lead times. 500 tonnes of steel structures on the work site in 8 weeks? Challenge accepted!”