Aluminium boat lift sales are not lagging behind

Aluminium boat lift sales are not lagging behind

Rene Blom: “Corona times have caused a boom”

During corona, people were looking for safe and attractive ways to get out and about. “Lots of people bought boats. And because there is a shortage of storage space for boats, the demand for boat lifts also grew,” says Rene Blom. He tells us Blom Bootliften responded to this and how SixPointTwo contributed.

Rene is in his element on and near the water. “The more active the sports, the more interesting it becomes to me. I have always loved sailing and windsurfing, but kite-surfing is my favourite at the moment.”

Own design

Water sports keep Rene very busy outside his free time as well. It all started with a polyester boat he once bought. “I needed a lift for it. There were plenty of steel boat lifts. But I really didn’t need a steel boat lift in my garden. I was working for a door manufacturer company at the time and they had their own aluminium construction department. So I decided to design and make my own aluminium boat lift.” This was initially purely as a hobby: “One for myself, one for a colleague, then one for an acquaintance, etc.”

Own company

Rene started his own business eight years ago involving two activities: on the one hand renovating real estate, while designing and marketing boat lifts on the other. Initially, the boat lifts were an afterthought. “First I developed the initial design and range.” Setting up a professional website was an important next step. “It has been non-stop ever since. Turnover has almost doubled in the past two years.”

Protecting the boat

Rene works with his son Rens in Blom Bootliften. “We supply and install aluminium lifts for light boats. This includes fibreglass boats and aluminium boats.” A boat lift offers protection. “A boat lift prevents a boat from getting stuck in ice or hitting the quay when there are a lot of waves. And the boat stays clean: which means you will not get any growth from algae or shellfish. Anti-fouling protection measures are therefore unnecessary, which is also better for the environment.” Theft prevention is another advantage: the lift can be equipped with a lock. Aluminium also has an important advantage. “Steel needs to be treated, galvanising for example, but it still remains sensitive to rust. Our lifts are made of untreated aluminium and last longer.”

For boats up to 900 kg

The product range consists of three types. “Type A is suitable for boats up to 500 kg. We can add supporting frames to make them suitable for jet skis as well.” Depending on the customer’s wishes, the boat is equipped with manual or electrical operation. Type B is suitable for boats up to 750 kg, and can be equipped with manual control and/or electric control. Finally, Type C can be used for boats up to 900 kg. “This type is only available with electrical operation.”

Development

Rene gradually perfected his design. “Our boat lifts have a fixed frame and a lifting frame. The lifting frame is identical for all types, which gives us more flexibility. We assemble the lifting frame in our workshop. We can then assemble the lift at the customer site, we can attach the lifting frame to the fixed frame in one simple operation. The frames are also made in such a way that we can make adjustments with our own welding machine.”

Production

In the beginning, Rene made the boat lifts himself in the evenings. But the sales volume increased and made this arrangement impossible. And so production was outsourced. “I worked with the first supplier for two years. I was not satisfied: hardly any orders were delivered that didn’t have something wrong with them.” Fortunately, through his hobby, he came into contact with Marco Wielink from SixPointTwo. “I taught him how to kite-surf.” And three years ago, that chance meeting led to him choosing to entrust the production of the frames to SixPointTwo. “They deliver great work: We have a 99% satisfaction rate. And if there is a problem, it is solved without any problems.”

New developments

Blom bootliften is focused on a market segment that is still growing. “Many new housing estates are being built near the water. If you have a terraced house and want to store a dinghy round the back, the space is quite limited. This means you need a smaller and lighter type of boat and boat lift.” Meanwhile, René is thinking ahead. “I can see a floating boat lift based on an aluminium construction that would be suitable for boats heavier than 900 kg, as well as houseboats.” Something to follow up of course!

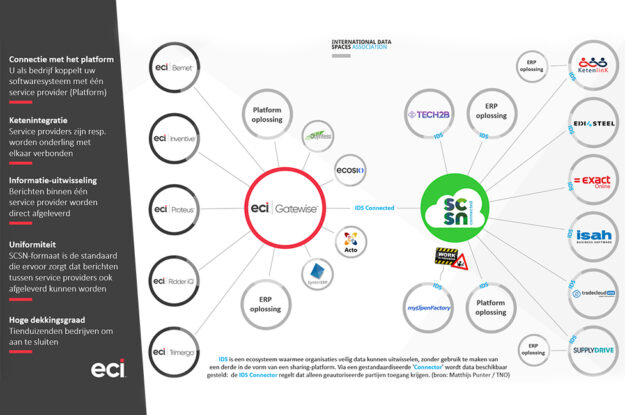

Sheet metal cutting is all about quality and cost efficiency. Therefore, the ERP system and the laser cutting machine must communicate well with each other in all phases of production control. “The biggest challenge is to always ensure the correct data gets from the ERP system to the laser cutting machine so the machine can provide feedback. Working with SixPointTwo, it was decided to first define the optimal process of production and control”, says KleinJan. He knows the ERP system through and through. “At the time, I was also involved in its implementation.”

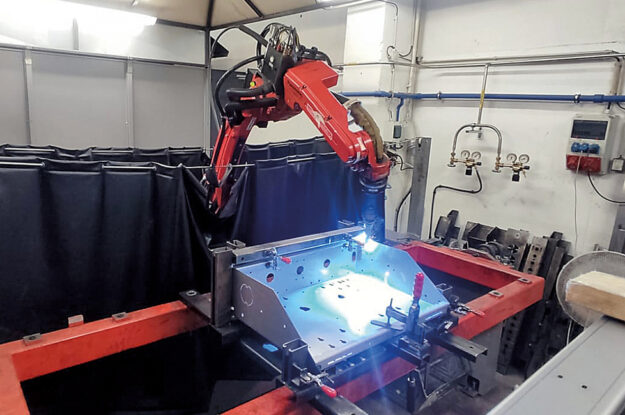

Sheet metal cutting is all about quality and cost efficiency. Therefore, the ERP system and the laser cutting machine must communicate well with each other in all phases of production control. “The biggest challenge is to always ensure the correct data gets from the ERP system to the laser cutting machine so the machine can provide feedback. Working with SixPointTwo, it was decided to first define the optimal process of production and control”, says KleinJan. He knows the ERP system through and through. “At the time, I was also involved in its implementation.” SixPointTwo first approached Valk Welding in 2016. The expansion of our production capacity necessitated additional welding capacity. “Especially the welding for serial production runs”, says van Boxel. A further increase in production led to the purchase of a second welding robot in 2021. “Like the first, this is also a complete welding robot system in which the welding robot is mounted on a stable H-frame. We also supplied DTPS: the software package for offline programming.”

SixPointTwo first approached Valk Welding in 2016. The expansion of our production capacity necessitated additional welding capacity. “Especially the welding for serial production runs”, says van Boxel. A further increase in production led to the purchase of a second welding robot in 2021. “Like the first, this is also a complete welding robot system in which the welding robot is mounted on a stable H-frame. We also supplied DTPS: the software package for offline programming.”